Reliable material handling without Wi-Fi-dependent 3rd party setups

Leader in mobile robotic equipment ROEQ has solved your AMR WiFi problems with GuardCom.

Leader in mobile robotic equipment ROEQ has solved your AMR WiFi problems with GuardCom.

Leveraging robust sensor technology for instant communication between ROEQ’s top rollers — conveyors on top of mobile robots — and stationary conveyors, this solution replaces cumbersome, Wi-Fi-dependent 3rd party setups that often cause delays and mismanagement in the transfer of goods between mobile robots and conveyors.

GuardCom is a seamless communication solution that enables Mobile Industrial Robots (MiR) AMRs equipped with ROEQ’s top rollers to communicate directly with the conveyor stations to initiate the transfer of goods between mobile robots and conveyors.

The solution consists of two products: GuardCom installed on the stationary conveyor station and GuardCom Connect installed on the autonomous mobile robot. Multiple GuardCom Connects can work with the same GuardCom and vice versa. GuardCom is compatible with all stationary conveyor stations, replacing 3rd party wireless devices.

The ideal vacuum gripper for palettizing and heavy-duty material handling. Save up to 90% on operating and maintenance costs with the new VGP20 electric vacuum gripper. The gripper can pick up bulky, heavy-duty payloads of up to 20 kg while being intelligent enough to handle a wide range of items, including those with porous and non-porous surfaces. The powerful, customizable OnRobot VGP20 easily handles these thinner and less expensive packaging materials, allowing you to save considerably on both automation and shipping costs.

Automated screwdriving to boost productivity and quality has never been easier, smarter, or more cost-effective. The OnRobot intelligent Screwdriver speeds setup and programming, with everything you need right out of the box. Simply mount the Screwdriver on any leading robot arm and install the appropriate bit, then enter screw length and torque directly into the robot’s user interface. Precise torque control and embedded axis eliminate the time and cost for additional integration and ensures consistent, accurate screw insertion. Changeovers to a different screw type or size take just minutes, reducing downtime and boosting ROI.

The OnRobot Soft Gripper is able to pick a wide array of irregular shapes and delicate items, making it ideal for pick-and-place applications in food and beverage production, as well as manufacturing or packaging. The gripper is available with three interchangeable silicon-molded cups. From eggs to fruit, to bottles or cans, food and beverage automation just got easier. Like all OnRobot grippers, the Soft Gripper offers seamless integration with the robot of your choice. The Soft Gripper operates without an external air supply, for no additional costs or complexity, and none of the dust or noise generated by traditional vacuum grippers.

Automating Monotonous Processes With Robots Has Fewer Obstacles Than Ever

Robots have provided tremendous benefits to companies looking to boost the productivity of their monotonous processes. Repetitive activities are ideal for robotic automation because they eliminate the fatigue and boredom from human automation that inevitably set in and reduce efficiency. Knowing this, businesses still hesitate to switch away from human automation...

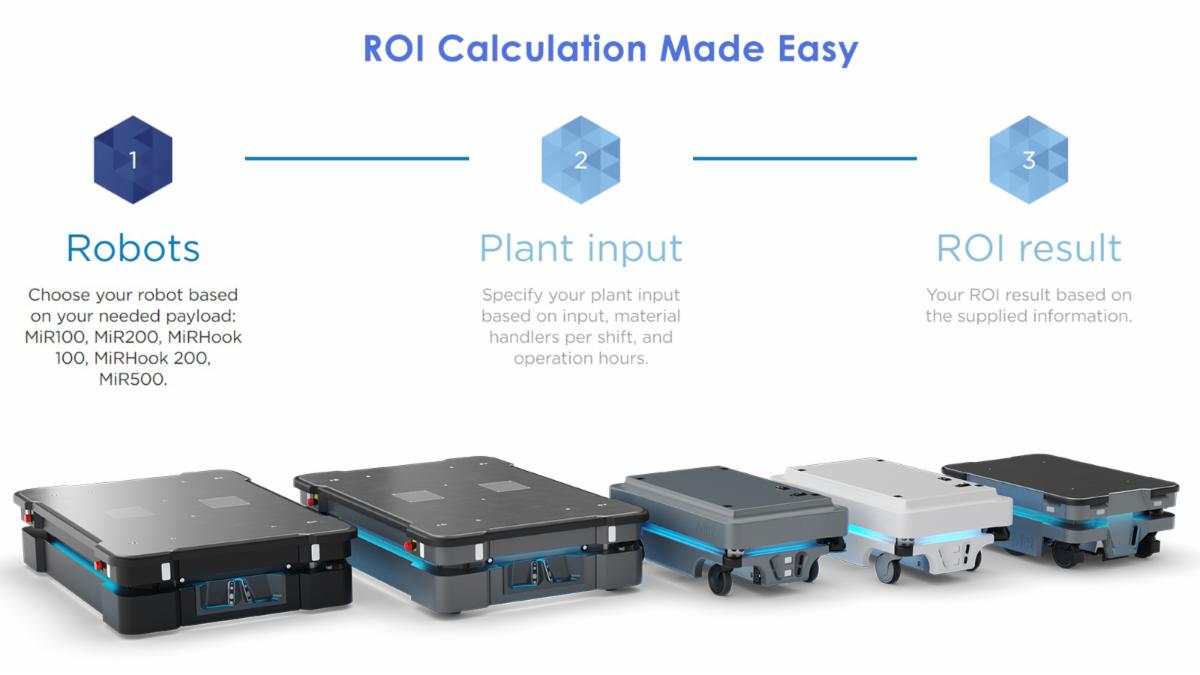

ROI For Robotic Implementation Just Keeps Getting Faster

Robotic automation has lead to game-changing benefits for facilities who have chosen to deploy robots in their manufacturing and processing operations. Notable applications include: repeatable assembly, warehouse transport, dispensing, inspection, machine tending, packaging, palletizing and more. Yet, nearly 55% of Automation World survey respondents said they still do not use robotic automation...

Accessorizing With Dress Packs Is Leading To More Productive Robotic Applications

Robotic cable management is often overlooked and saved as the last part of the design process when implementing robotic solutions, despite being cited as the number one reason for downtime in robotic applications. Common cable issues are tangling, corkscrewing, fraying and complete breaks, all of which can lead to costly downtime. Improper cable management can also restrict the movement of a robotic arm, directly affecting the process performance...

AMRs Are Changing The Way Food & Beverage Companies Operate

In an age when warehouse and distribution centers' productivity levels are tracked down to the second, workers in the food & beverage industry are pushed to help improve production and grow revenues, sometimes at the cost of their own safety. Not only can increased expectations on human output be a recipe for unsafe working conditions, but they can also lead to expensive operational costs — realized as damaged inventory or equipment, caused by forklifts or human error...

BIG Robots For BIG Jobs Are Getting Safer

BIG Robots For BIG Jobs Are Getting Safer

More decision-makers are coming to the realization that collaborative robots — or cobots — are the future of workplace automation. They have become a friendly "face" working alongside humans, providing mechanical muscle to help drive efficiency. Some research analysts forecast a 57% growth rate in robot shipments from 2016 to 2022 worldwide. As cobots become more versatile and able to assist with larger applications, the question of employee safety always looms. To demonstrate their safety lets look at a common large scale application....

Fleet Management Software Improves Mobile Robot Collaboration

Fleet Management Software Improves Mobile Robot Collaboration

Manufacturers are recognizing the significant benefits that autonomous mobile robots can offer versus conventional logistic solutions, like forklift and conveyor systems. These conventional solutions simply don't allow the level of flexibility or adaptability that AMR's provide, and they can require expensive and disruptive infrastructure reconfiguration to meet the ever-changing demands of consumers...

INCREASED END OF ARM TOOL EFFICIENCY IS OPENING DOORS TO NEW APPLICATIONS

INCREASED END OF ARM TOOL EFFICIENCY IS OPENING DOORS TO NEW APPLICATIONS

As robots become further integrated into all industries, savvy businesses are exploring different ways to utilize them in multiple processes. The three main categories that encompass most industrial robot operations are Material handling, Processing Operations and Assembly and Inspection. Selecting an End of Arm Tool (EOAT) that is best suited to accomplish the defined task(s) is imperative...

From AGVs to AMRs

From AGVs to AMRs

As automation becomes the new norm for manufacturing and warehousing operations in the Industry 4.0 era, the options to help you achieve it are rapidly evolving. Technologies such as unmanned forklifts, collaborative robotic arms, improved sorting/collection, and smart conveyors are advancing as costs continue to decline; making these options more accessible for businesses of all sizes...

Robot programming (Teaching) is getting easier and easier

Robot programming (Teaching) is getting easier and easier

As robots have evolved to become more efficient so has the process of programming them. A common misconception about robot programming is that you must be a highly skilled programmer to get a robot up and running...

Easily connect conveyors to maximize process flow

Easily connect conveyors to maximize process flow

Real efficiency in logistics automation is achieved when the entire workflow is handled by robotics solutions that communicate smoothly with each other. That’s the vision behind ROEQ’s Top Roller that automates load and unload operations for the MiR series...

Robotic Packaging Automaton

Robotic Packaging Automaton

Packaging has been an important part of business operations for centuries. The $900 billion industry has emerged as an integral process of every business, from multi-million dollar corporations to small-town mom and pop shops. Protecting products during transit isn't an inexpensive endeavor, either...

Robotic Integration When and Where It's Needed Most

One thing that has been on the minds of many during the current market situation is how to deal with labor shortages — in manufacturing, in material handling and in food and beverage production. The Society of Manufacturing Engineers (SME) reports that 89% of manufacturers are having difficulty finding skilled workers...

The Evolution Of The Gripper

The Evolution Of The Gripper

It has been roughly 50 years since the first readily controllable gripper was created. The Stanford arm utilized two straight-bar fingers with linear motion that slid together to grip and release objects. Since, grippers have continued their evolution from three-finger graspers to robotic hands with flexible joints, contactless grippers that use suction and flexible cups...