Machine Tending with collaborative robots (cobots) is changing industry!

The process of machine tending involves using a collaborative robot to oversee a machine to perform operations to assist with operator processes. Incorporating machine tending has may advantages such as:

- Reduce injury risk

- Raise productivity

- Automate load/unload parts

- Perform finishing applications

- Polishing, sanding, deburring, etc

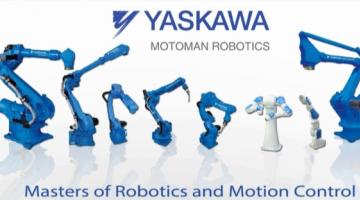

C&E offers this and many other application solutions pairing Yaskawa-Motoman Smart Series cobots with other top vendors from our robotics line.

C&E's camera crew got the opportunity to accompany our Robotic Business Developer Dana Poling to Yaskawa Motoman's US headquarters to get an exclusive look at their new human collaborative robot, the HC20.

The human-collaborative robot HC10 is for customers looking for easy automation, meaning an industrial robot to automate tasks that require it to work in close proximity to humans.

This complete electric random orbital sander from OnRobot is designed for use with industrial cobots and can be used for almost any automated surface finishing application, from sanding and buffing to polishing and cleaning. The Sander is available with everything you need to get started right away, and operates without external air supply, for no additional costs or complexity, and none of the dust or noise generated by traditional air sanders. Contact a C&E specialist for a quote or more information about this CEntelligent solution.

Murrplastik's Flexible Holder System for Cobot is ideal to bundle and protect power cords and air lines during operation. This also increases the enclosed cords life span by reducing twisting which can lead to fraying. Contact a C&E Technology Consultant for more details.

Yaskawa Smart Series is a new generation of collaborative robotics, with powerful application capabilities for which Yaskawa is known. These robots are for customers looking for easy automation, meaning an industrial robot to automate tasks that require it to work in close proximity to humans.

OnRobot now offers a Soft Gripper that is able to handle a wide array of irregular shapes and delicate objects in food and beverage, cosmetics and pharmaceuticals production, as well as manufacturing or packaging.

The FHS flexible holder system from Murrplastik is a unique modular holder system for dynamic energy supply to cobots. It provides a secure, non-slip grip and fits on different surfaces and radii.

OnRobot product range features a wide assortment of tools for collaborative applications, including: electric and vacuum grippers, the award-winning Gecko gripping technology, force/torque sensors, a 2.5D vision system, screwdriver, sander kits and tool changers. This new combination of offerings from OnRobot makes it quicker and simpler to automate tasks such as packaging, quality control, materials handling, machine tending, packaging, assembly, and surface finishing.

Murrplastik provides unique solutions to challenges in the areas of cable protection, cable marking, labelling, automation and robotic equipment. Their high-tech plastic products can be found in just about every industrial sector, ranging from the rail - and automotive industry through toolmaking and mechanical engineering to electrical and medical engineering, packaging and woodworking.

Murrplastik provides unique solutions to challenges in the areas of cable protection, cable marking, labelling, automation and robotic equipment. Their high-tech plastic products can be found in just about every industrial sector, ranging from the rail - and automotive industry through toolmaking and mechanical engineering to electrical and medical engineering, packaging and woodworking.

SCHUNK offers the world's largest range of clamping technology and gripping systems and with more than 2,550 SCHUNK grippers, the broadest range of standard gripper components on the market. The entire gripping system program comprises more than 4,000 components.

SCHUNK offers the world's largest range of clamping technology and gripping systems and with more than 2,550 SCHUNK grippers, the broadest range of standard gripper components on the market. The entire gripping system program comprises more than 4,000 components.

Yaskawa is the world's largest manufacturer of AC Inverter Drives, Servo and Motion Control, and Robotics Automation Systems.